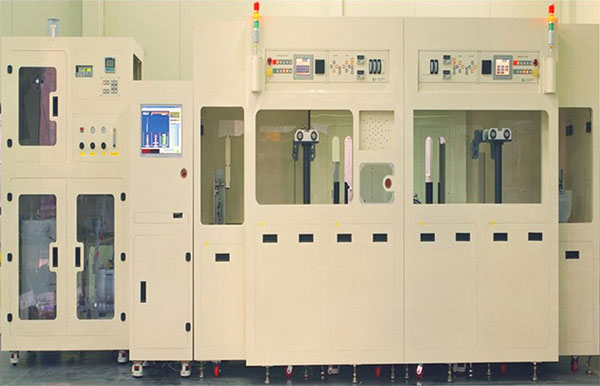

- · Dimension: 13,480 * 7,700 * 5,980

- · Mode: Auto Mode

- · Control: PLC

- · 6G ~ 8.6G Half size compatible

| Air Jet Mill | |

| Milling Capacity | 5~50kg/hr* |

| Milling Housing Meterial | SUS 304 |

| Mill Zone | Circle Type : Zirconia Ceramic |

| Mill Zone Top Plate | Zirconia Ceramic |

| Mill Zone Bottom Plate | Zirconia Ceramic |

| Ejector Nozzle | Material : SUS 304 |

| Size : 7mm | |

| Side nozzle | Material : SUS 304 |

| Size : 2.5mm * 6 way type | |

| Input Press | Gauge & Solenoid V/V Control |

| Using Press Air | over 6kg/cm³ |

| Sample Out Line Size | 6s Ferrule – SUS304, Butterfly V/V 150A |

| Filtering Size | 0.5μm |

* Sample type and amount may vary with final particle size.

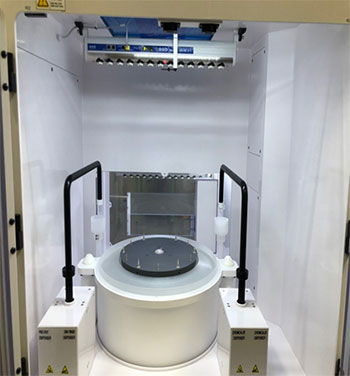

| Air Jet Mill | |

| Milling Capacity | 100~500g/hr* |

| Milling Housing Meterial | SUS 304 |

| Mill Zone | Circle Type : Zirconia Ceramic |

| Mill Zone Top Plate | Zirconia Ceramic |

| Mill Zone Bottom Plate | Zirconia Ceramic |

| Ejector Nozzle | Material : SUS 304 |

| Size : 6mm | |

| Side nozzle | Material : SUS 304 |

| Size : 1.5mm * 5 way type | |

| Input Press | Gauge Control |

| Using Press Air | over 6kg/cm³ |

| Sample Out Line Size | 1.5s Ferrule – SUS304, Glass Bottle & PTFE Cap |

* Sample type and amount may vary with final particle size.

| Air Jet Mill | |

| Milling Capacity | 5~50kg/hr* |

| Milling Housing Meterial | SUS 304 |

| Mill Zone | Circle Type : Zirconia Ceramic |

| Mill Zone Top Plate | Zirconia Ceramic |

| Mill Zone Bottom Plate | Zirconia Ceramic |

| Ejector Nozzle | Material : SUS 304 |

| Size : 6mm | |

| Side nozzle | Material : SUS 304 |

| Size : 1.5mm * 5 way type | |

| Input Press | Gauge Control |

| Using Press Air | over 6kg/cm³ |

| Sample Out Line Size | 1.5s Ferrule – SUS304, Glass Bottle & PTFE Cap |

| *Option | N2 Purge box |

* Sample type and amount may vary with final particle size.