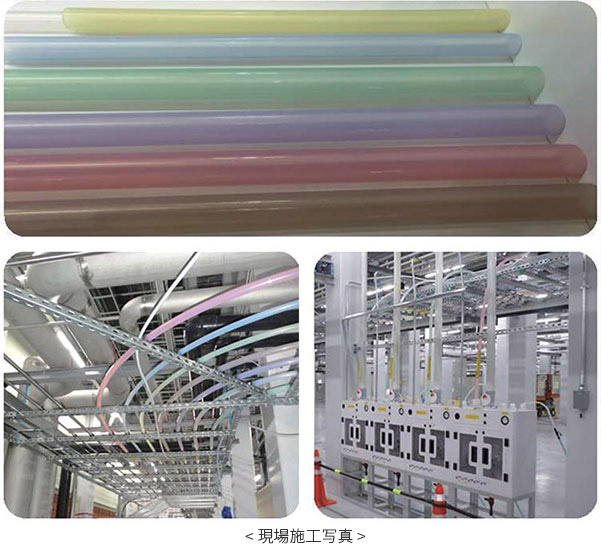

- · 各薬液に対応する配管を色分けし、危険要因を最大限に抑え、目を保護

- · 長距離施工によるLeak Pointの最小化

- · 一体型施工による作業効率の向上・30%のコスト削減

- · 優れた摩耗力・耐摩耗性

- · 使用温度の上限値5000℉ (260℃)

- DUAL CONTAINMENT TUBE

- Features

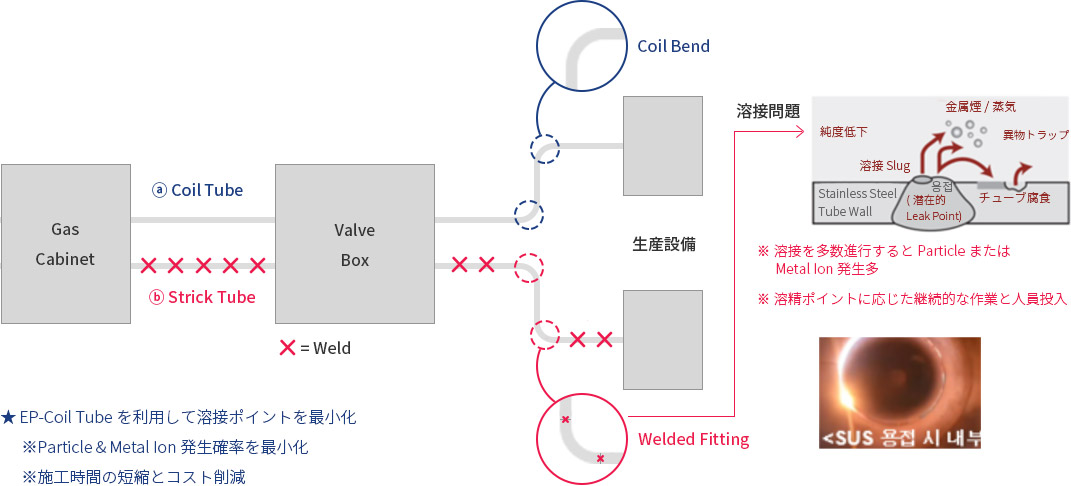

- EP COIL TUBE

- Maker Introduce

Maker

Introduce

- 特殊配管部品およびサービスを提供

- ISO規格Class-10クリーンルームで洗浄、テスト、梱包を進行

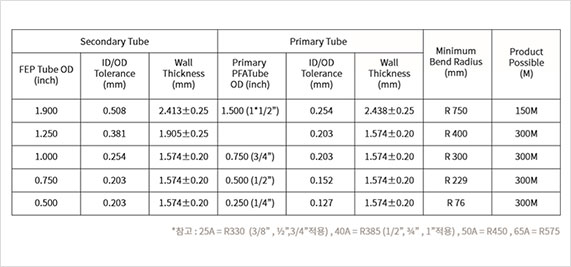

- EP-Coil Tube Evaluation Data

Particle test #1 – 180º Bending → Straight restoration

※10Min(分)以降Particle未検出確認(人に対するエラーも10分以内に解決)

Particle test #2 – Roller Use Straight Bending

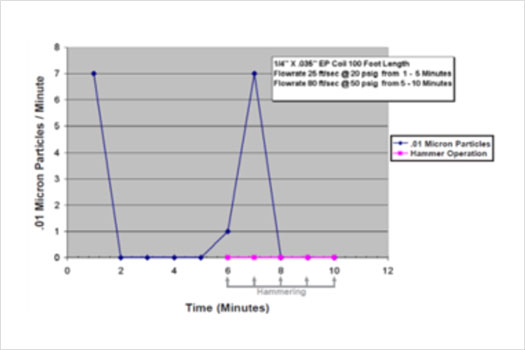

- How to install EP-TUBE (COil : Stick) #1

ⓐ Coil Tube 施工(改善案)

ⓑ Stick Tube (既存)

- How to install EP-TUBE (COil : Stick) #2

- Why use EP-Coil Tube?

SUS 配管溶接

- – 高温の熱で溶接棒を溶融させて配管-配管接続の方法

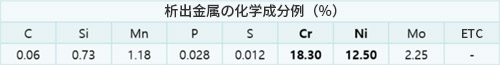

- – 溶接棒成分表

グローバル企業EP-Coilの適用

- – TSMC、Intel、Micronなど2016年から新規ライン適用

EP-Coil Tube 適用

- – 溶接箇所減少 = Weak point 減少 → Metal 溶出点減少

- – 400M作業時の溶接箇所

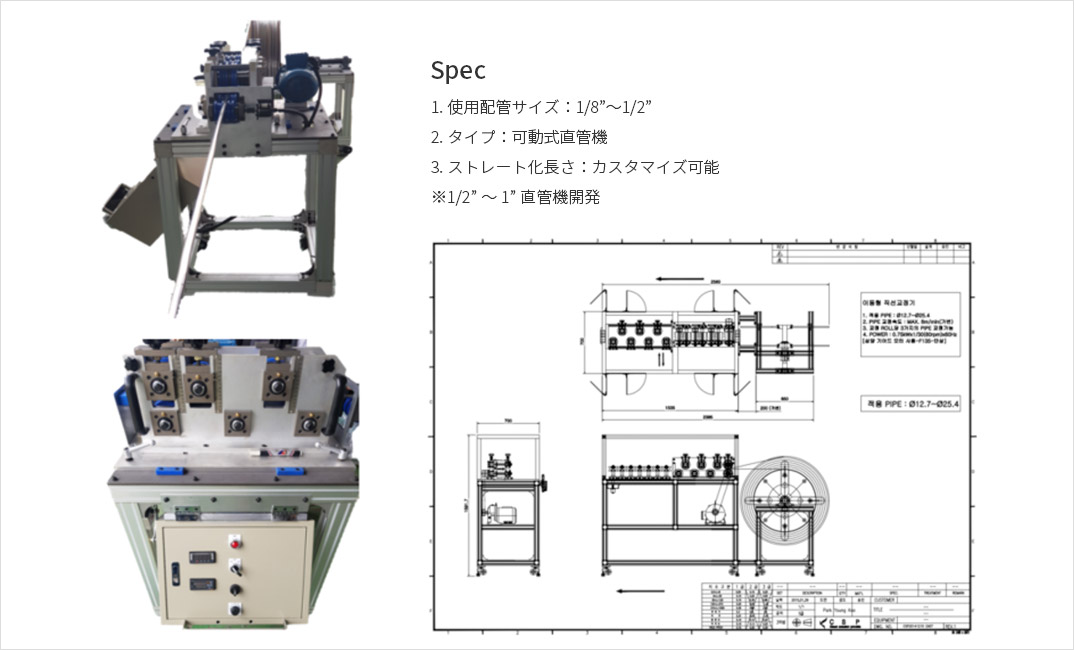

- 直管機

- FFKMフッ素O-RING

- Solrez’s selection guide for process

| Process | Compound Number | Service temp(oC) | Color | Equivalent Compound |

| Metal CVD Process LP-CVD Oxidation Diffusion Lamp Anneal RTP Ash ALD |

8318 | 320 | Light yellow | 4079,8900 7075UP,653 |

| 8107 | 320 | Black | 4079,8900 7075UP,653 |

|

| 9578 | 300 | Light yellow | 9100, 9300M XRZ |

|

| 9575 | 300 | White | 8475, 8575 | |

| 9568 | 280 | Light yellow | 8002 | |

| 9566 | 280 | White | E-38 | |

| Wet Etching Photo litho-graypy Stripping Copper plating |

9308 | 250 | Light yellow | 8002.93 |

| 9307 | 250 | Black | 6375UP | |

| 7709 | 230 | Amver translucent | Amor crystal | |

| 7708 | 230 | Light yellow | Ultic Armor | |

| 6907 | 220 | Black | - | |

| 6607 | 250 | Black | Fluoraz888 | |

| 5901 | 200 | Blue | - |

- Solrez’s Compound selection guide

| Compound number | Service temp(oC) | Color | Equlvalent Compound | Recommend Processing |

| 8318 | 320 | Light yellow | 4079,8900,7075UP,653 | Oxidation diffusion(02,N2,CI2) Metal CVD(NF3,SiH4,F2,CI2) |

| 8107 | 320 | Black | 4079,8900,7075UP,653 | Oxidation diffusion(02,N2,CI2) Metal CVD(NF3,SiH4,F2,CI2) |

| 9578 | 300 | Light yellow | 9100,9300,XRZ | PECVD/ALD/HDPCVD (TMS,SiH4,NH3,NF3,SiF4) |

| 9575 | 300 | White | 8475,8575 | Infrared light |

| 9568 | 280 | Light yellow | 8002 | Ash(2,CF4,NH3,CHF3),Dry etch |

| 9566 | 280 | White | E-38 | Ash(2,CF4,NH3,CHF3),Dry etch |

| 9308 | 280 | Light yellow | 8002,9300 | Wet etch,strip,copper plating (HN03,HF,H3PO4,H202,CuSO4) |

| 9307 | 250 | Black | 6375UP | |

| 7709 | 230 | Amber translucent | Amor crystal | All CVD,Dry etch and plasma ashing equipment For semiconductor and LCD |

| 7708 | 230 | Light yellow | Ultic Armor | |

| 6907 | 220 | Black | - | Excellent solvent resistance(FKM) |

| 6607 | 250 | Black | Fluoraz888 | Wet etch |

| 5901 | 220 | Blue | - | O2,O3 Plasma |

- High temperature FFKM special O-ring

- Grade: Solrez8318

- Material: FFKM

- Service temp: 320℃

- Color: light yellow

- Hardness: 75(shore A)

- Tensile strength: 14.2MPa

- Elongation: 210%

- Compression set: 18%(270℃ x 72hrs)

- Application:

– Oxidation diffusion(O2,N2,CI2)

– Metal CVD(NF3,SiH4,F2,CI2)

- Grade: Solrez8107

- Material: FFKM

- Service temp: 320℃

- Color: Black/li>

- Hardness: 75(shore A)

- Tensile strength: 12.2MPa

- Elongation: 180%

- Compression set: 18%(200℃ x 72hrs)

- Application:

– Oxidation diffusion(O2,N2,CI2)

– Metal CVD(NF3,SiH4,F2,CI2)